Page 5 of 6

Re: Cabbing to carving conversion

Posted: Sat Sep 26, 2015 4:53 pm

by jakesrocks

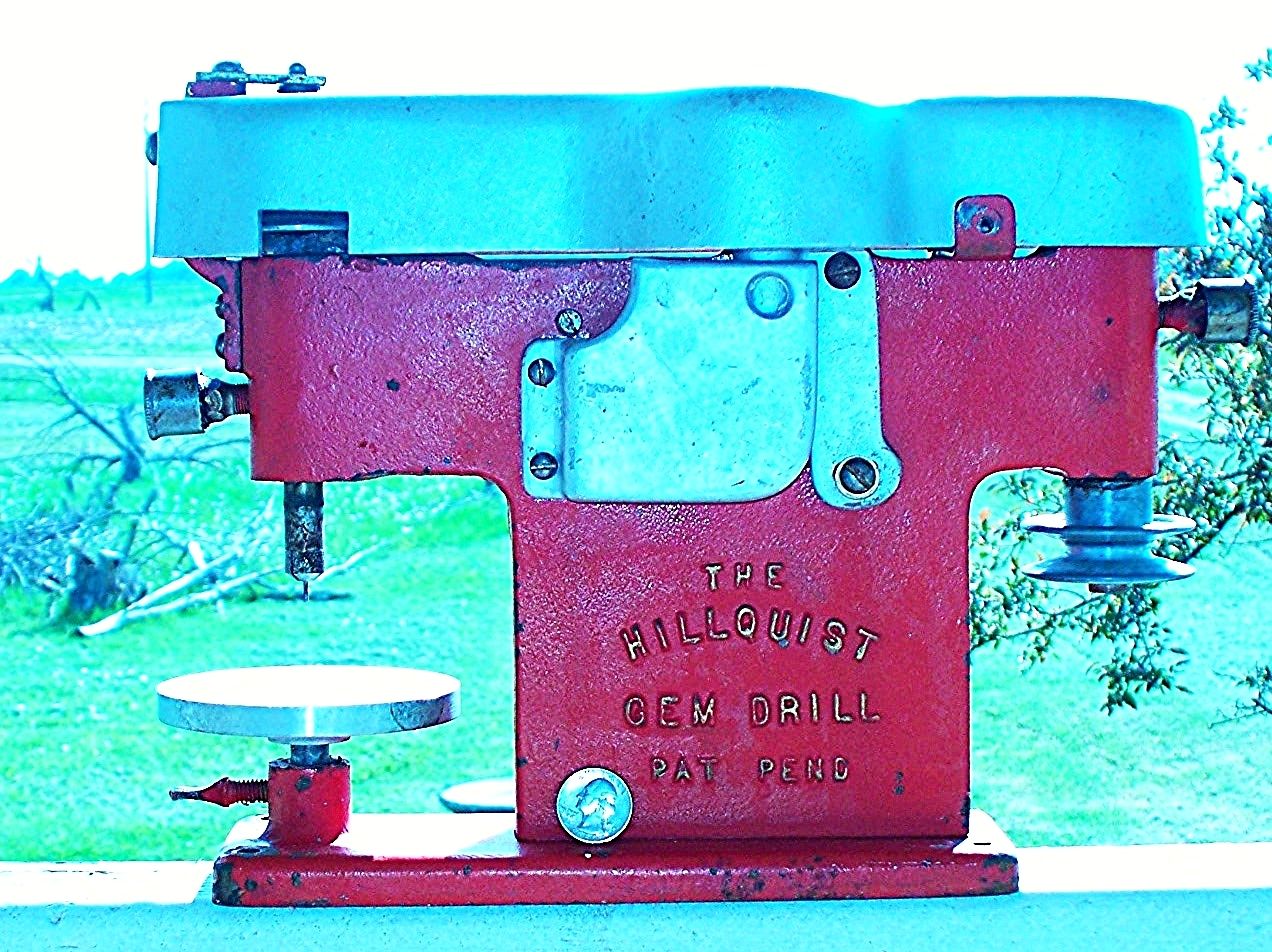

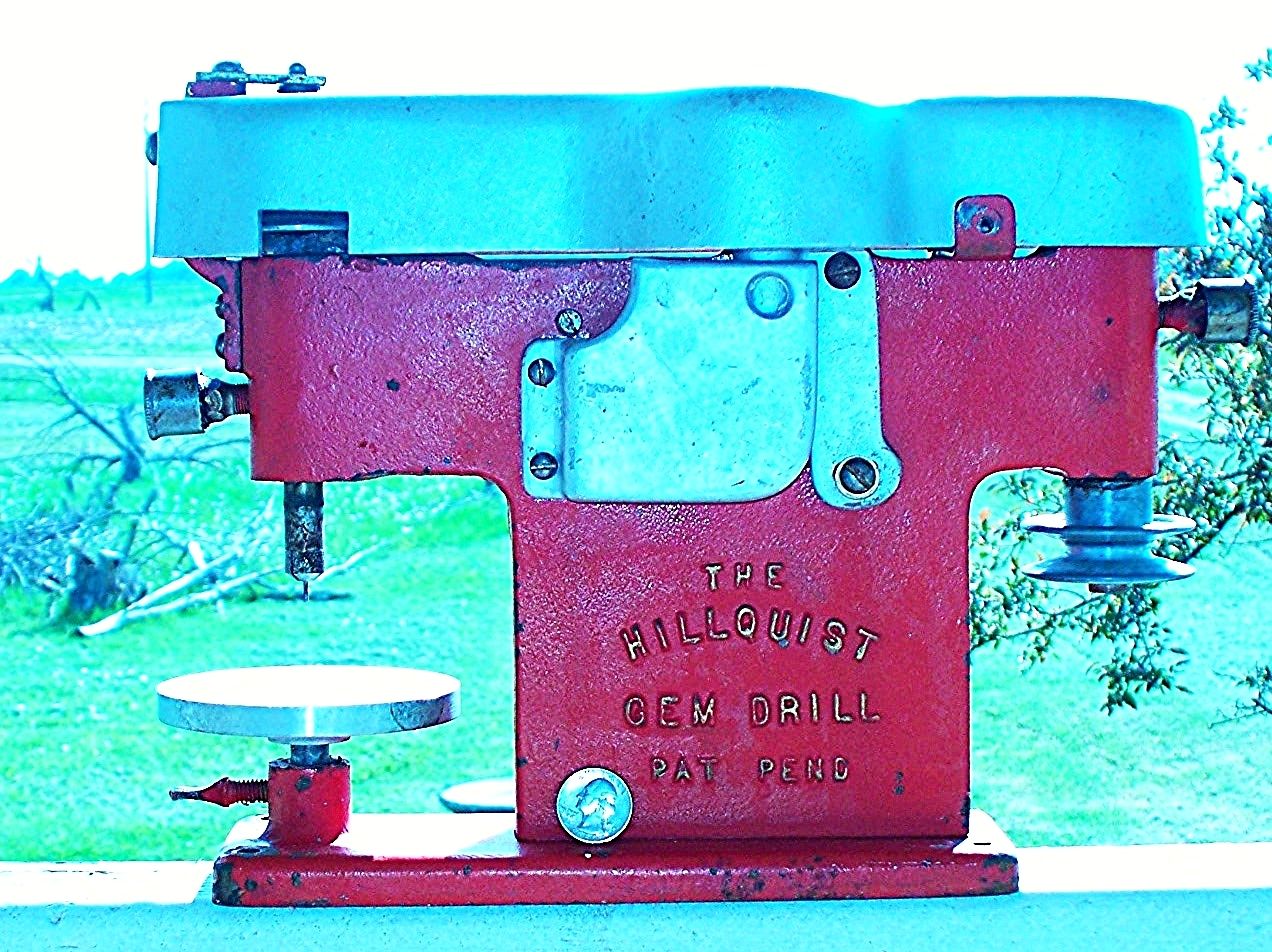

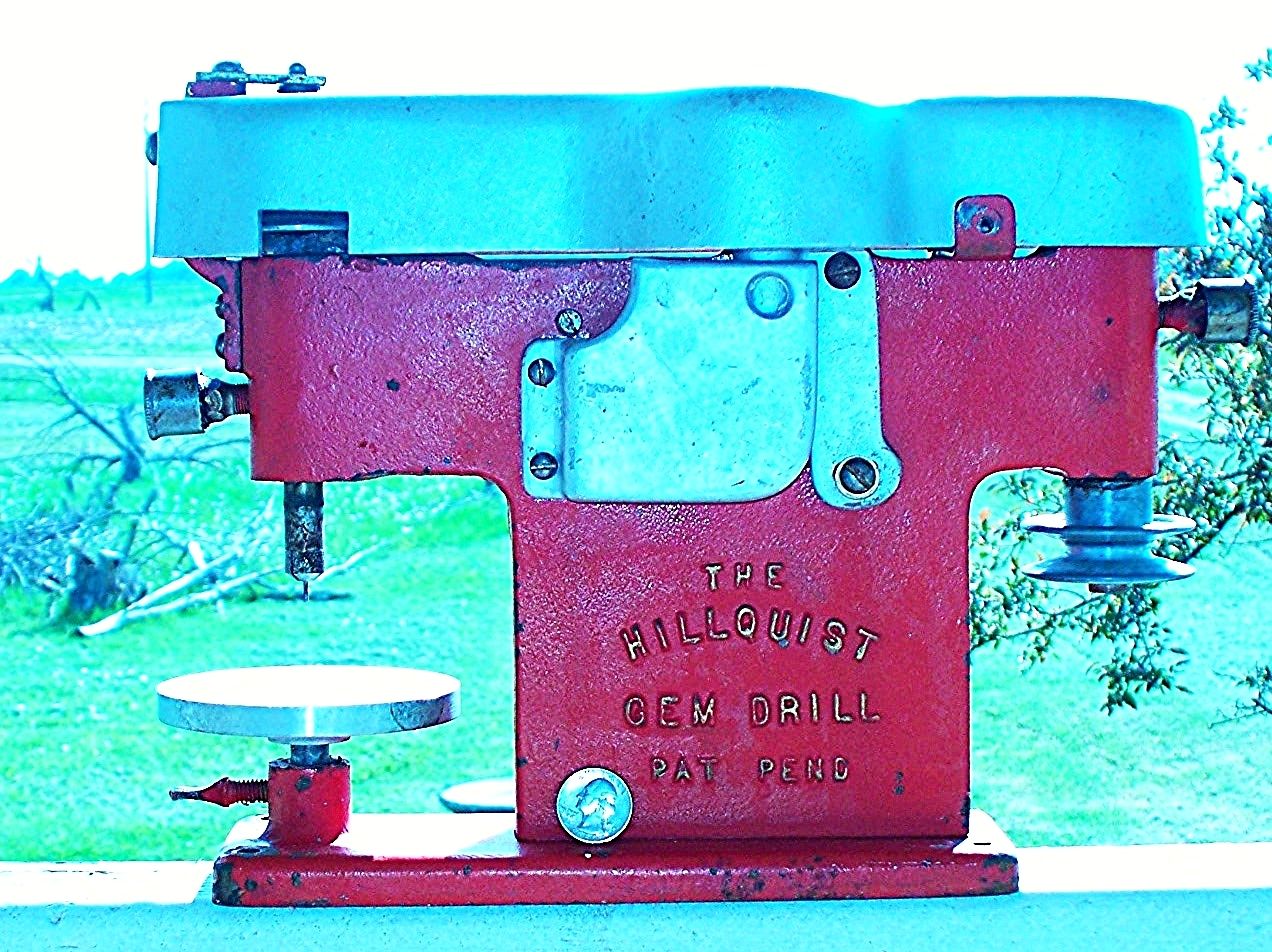

Pink, this is the Hillquist automatic gem drill. When working properly, it automatically raises & lowers the drill to allow clearing grit from the hole, and coolant water to run into the hole. This one needs new round belts and a new spring. I'll probably never use it. I just want to restore it and put it on display with some other vintage equipment & supplies I have. You can guess the age of this piece by the grease cups on both ends.

Don't know if my wife will share me. I've been tearing things apart & putting them back together since I was old enough to open the old mans tool box. Just natural curiosity I guess. I love seeing what makes things work, and seeing if I can make broken things work again.

Re: Cabbing to carving conversion

Posted: Wed Oct 07, 2015 10:29 pm

by jakesrocks

Got the motor for my cabber rebuild all wired today. Waiting for a dry day to soda blast the machine down to bare metal. Drizzled all day today. High humidity & soda blasting don't mix.

Re: Cabbing to carving conversion

Posted: Wed Oct 07, 2015 10:32 pm

by kjsspot

This Soda blast goes well with high heat & humidity.

Re: Cabbing to carving conversion

Posted: Wed Oct 07, 2015 10:48 pm

by jakesrocks

LOL. you can keep the humidity.

Re: Cabbing to carving conversion

Posted: Thu Oct 08, 2015 12:40 am

by jakesrocks

Bump Wheel. there's no rubber or sanding strip on this one. At about 2:00 on the picture is a slot which runs all the way across the wheel. Next to it on the inside of the wheel is what looks like a bolt. This bolt also has a slot in it. One end of a sanding strip goes through the slotted rim and through the bolt. The strip is then wrapped around the wheel and the other end is pushed through the slot & bolt. The bolt is turned with a screw driver to tighten the strip around the outside of the wheel. A lock nut is tightened to lock the strip in place. After tightening the belt there is a small gap between the ends of the belt. In use, this causes a slight bump to be felt while sanding. Thus the name "bump wheel".

Re: Cabbing to carving conversion

Posted: Thu Oct 08, 2015 1:05 am

by opalcreations

Ahhh, the good old fashioned bump wheel!

Thanks for showing us!

Re: Cabbing to carving conversion

Posted: Thu Oct 08, 2015 1:37 am

by jakesrocks

Does it bring back memories ? Posted it to show Pinkdiamond what a bump wheel looked like.

Re: Cabbing to carving conversion

Posted: Thu Oct 08, 2015 1:41 am

by opalcreations

Oh yes, it does.

This was the first wheel I ever used back in the day, I remember my hands tingling after using it from all the constant vibration.

Re: Cabbing to carving conversion

Posted: Thu Oct 08, 2015 2:19 am

by jakesrocks

Yup. I cut my cabbing teeth on SC grinding wheels & bump wheels too. Those were the good old days. These youngsters have got it too easy with their diamond wheels to learn on.

Re: Cabbing to carving conversion

Posted: Thu Oct 08, 2015 3:39 am

by PinkDiamond

Thanks so much for showing me that. Do many cutters still use bump wheels?