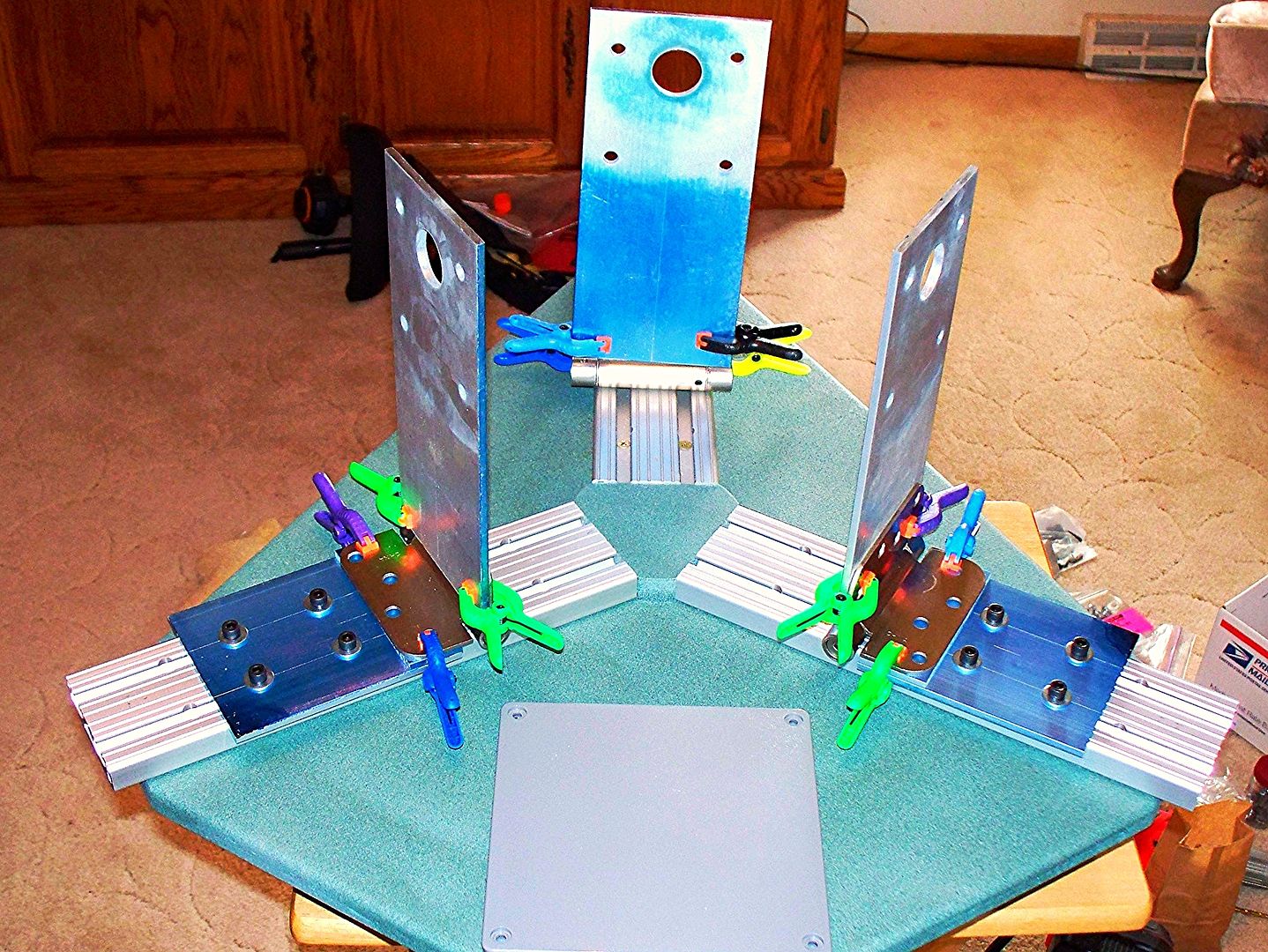

In the beginning there were parts. Lots of parts. And my supervisor Jake.

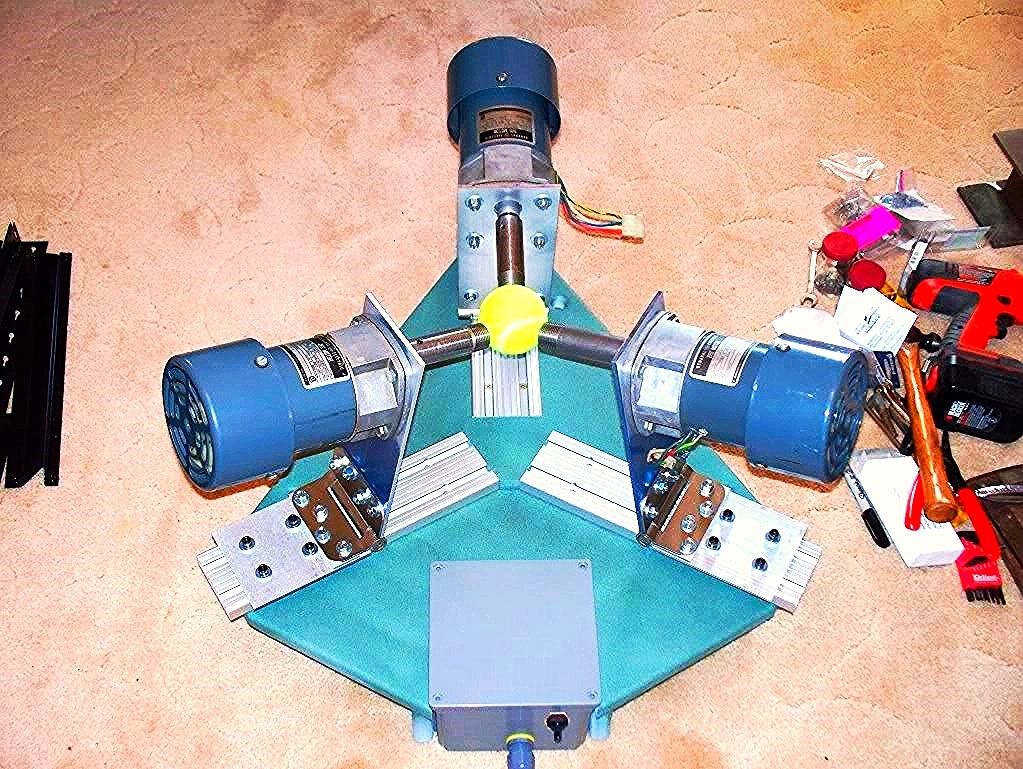

The motors are salvaged from old IBM copy machines. They're gear head motors with an output speed of 105.7 RPM. These motors are now almost impossible to find. I was wise enough to buy a couple extras while they were available.

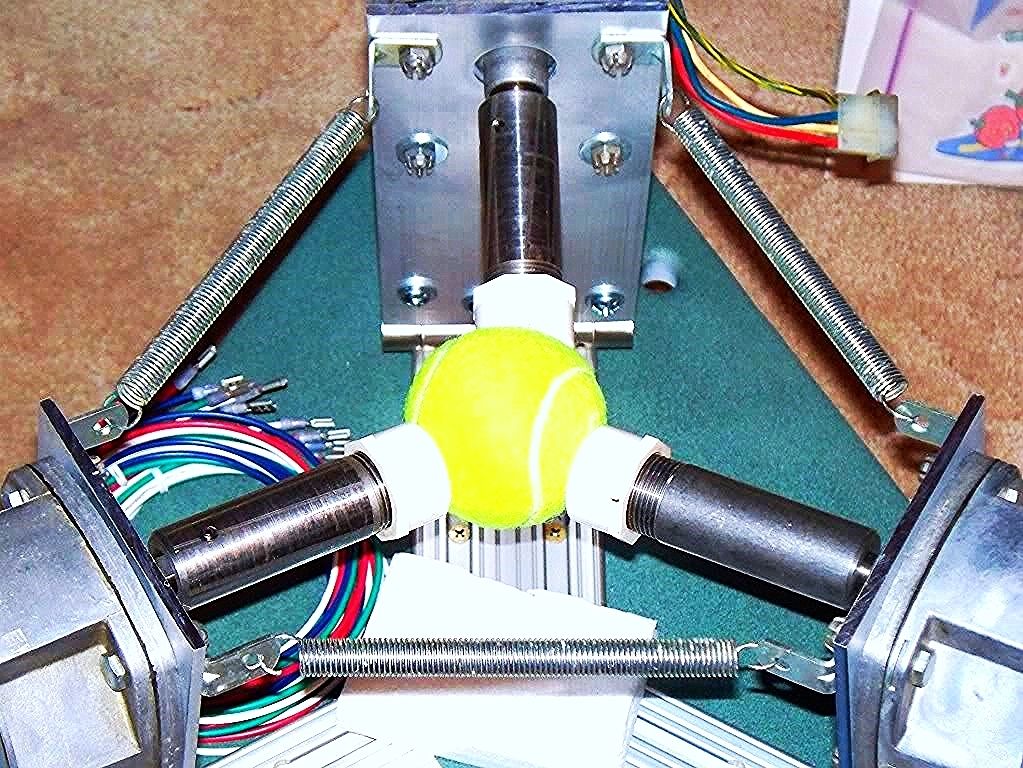

A friend machined 3 adapters for me which will adapt 3/4" pipe bell reducers to the 1/2" motor shafts. The bell reducers will be my cutter cups.

The tracks for my motors to mount on are aluminum T- track extrusions. I bought factory off cuts for the tracks, and bought the special t- nuts and bolts to go with them at the same time.

Also in the first pic, right by Jake's nose are bottles of aircraft grade nuts & bolts of various lengths & sizes. These were salvage from an aircraft plant my father worked at many years ago.

Still more parts.

A 6" square water tight box and watertight feed thru fittings for wiring were purchased at the local Menards store. This will contain the 3 motor condensors, a terminal strip a power switch and bunches of wiring. Also in the second pic is a Mil Grade water tight switch.

To be continued after supper.